Laser Glass Cutting Machine featuring modular design allowing easy upgrades and customization to meet evolving glass cutting demands To Accuracy±0.01mm

-

تقسيم تردد نبض مصدر الليزر1-100 كيلو هرتز

-

سرعة القطعقابل للتعديل من 0-500 مم/ثانية

-

حجم العمل610*700mm × 2 قابل للتخصيص

-

التنقلمزودة بعجلات شاقة لسهولة الحركة وإعادة التدوين ، مع آليات القفل للاستقرار

-

البعد2150 مم × 2080 مم × 1960 مم / 2550 مم × 2080 مم × 1960 مم

-

اسمآلة قطع وتقسيم الزجاج (الكل في واحد)

-

عرض النبض<10ps

-

جودة الشعاعM² <1.2

-

منتجماكينة قطع الزجاج بالليزر

-

الطول الموجي لليزر1064 نانومتر

-

المواد القابلة للتطبيقأكريليك، زجاج، ورق، بلاستيك، كريستال

-

تكنولوجيا القطعالليزر

-

تردد النبض1 هرتز - 1000 كيلو هرتز

-

منطقة العمل1500mm × 3000mm

-

دقة التجزئة± 0.01 ملم

-

اسم المنتجماكينة قطع الزجاج بالليزر

-

الليزر80 واط

-

منطقة القطع1000 مم × 1000 مم

-

النطاق المطبقزجاج

-

تنسيق ملف الدعمPLT، DXF، BMP، AI، DST، DWG، إلخ.

-

موادالزجاج ، الأكريليك ، البلاستيك ، الخشب ، إلخ.

-

خدمة الحياةحياة طويلة

-

حجم المنضدة1300 مم × 2500 مم

-

مكان المنشأالصين

-

اسم العلامة التجاريةCKD

-

إصدار الشهاداتISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

الأسعارNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Laser Glass Cutting Machine featuring modular design allowing easy upgrades and customization to meet evolving glass cutting demands To Accuracy±0.01mm

Product Description:

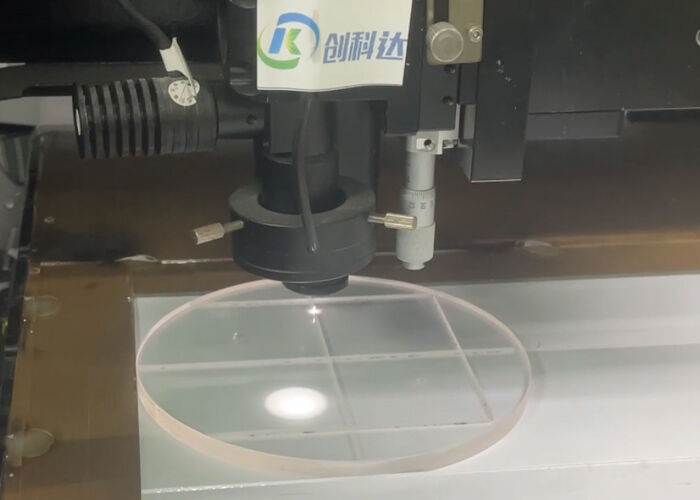

This device is an apparatus for efficient cutting of glass by high-energy laser, where the cutting is for profile machining, and CO₂ laser-assisted cracking used to achieve the cutting and cracking of glass.

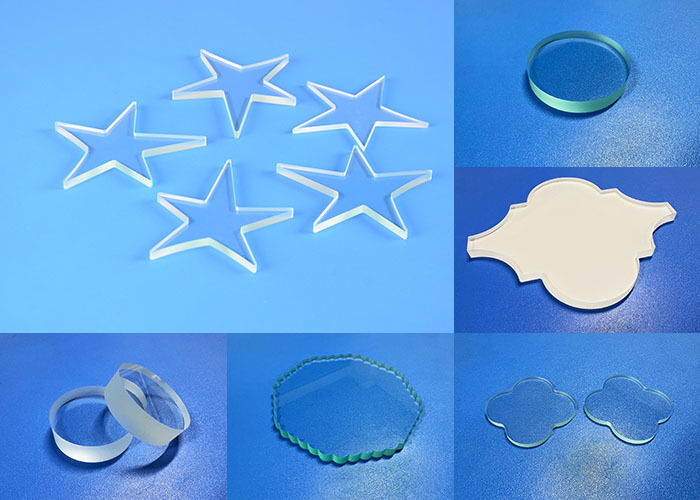

Picosecond laser precision processing, non-contact cutting, no stress influence, smooth incision, no edge breakage, no cracks, stable consistency, no need for secondary polishing or grinding, meeting various cutting needs of glass and other materials.

![]()

![]()

Technical Parameters:

| Name | Glass Cutting And Splitting Machine (All-in-One) |

| Positioning Accuracy | ±2μm |

| Laser Type | Infrared Picosecond |

| Cutting Width | 0.03-25mm |

| Cutting Thickness | Ultra-clear Glass Single Cut ≤19mm, Blue Glass Double Cut ≤19mm |

| Working Voltage | 220V |

| Cutting Precision | ±0.01mm |

| Working Environment | 26℃ |

| Brand | CKD |

| Customizable Options | Custom Options Available For Table Size, Laser Power (up To 500W), And Special Cutting Heads (like For Curved Or Micro-level Cutting) To Meet Specific Needs |

Applications:

Can process "ultra-clear glass, regular white glass, high boron silicate glass, quartz stone glass", etc., mobile phone cover, car glass cover, camera glass cover, etc., mobile phone sapphire cover, camera sapphire cover, sapphire light strip, K9 glass, filter film cutting, reflector cutting, etc. Optical glass.

![]()

![]()

Introduction to the company:

Shenzhen CKD Precision Mechanical & Electrical Co., Ltd. was established in 2010. lt is a Ultrafast laser equipment manufacturer and automation new intelligent manufacturing solution provider that integrates R&D, production, sales, and service. After more than ten years of deep cultivation and accumulation, the company has accumulated more than 70 patents, passed CE certification,1S09001 quality management system certification, and Intellectual Property Management System Certification. lt is a national high-tech enterprise and a Shenzhen Professional, Refined, Special, and Innovation Enterprise.

The company has a sheet metal workshop, machining workshop, assembly workshop, and process development and debugging workshop, covering R&D, Production, Testing, Sale & after service.

Up to now, the company has strong R&D team that has been engaged in laser structural design and laser application technology for many years. With a strong R&D ability and core software technology, the company has achieved innovation and break-through in product technology in fields such as ultra fast laser cutting, laser drilling, TFT-LCD screen laser repair, semiconductor plastic sealing and debonding, diamond grinding, laser welding, and laser marking. Especially in the processing of hard and brittle materials such as glass and ceramics, TFT-LCD repair, semiconductor plastic sealing and debonding, as well as diamond grinding and other automated new intelligent manufacturing, we provide cus- tomers with low-cost, high-quality, and high-efficiency solutions,making contributions to customer with value-added,innovation,and development.

![]()

![]()

![]()

Packing and Shipping:

Product Packaging:

The Laser Glass Cutting Machine is carefully packaged to ensure it arrives safely and in perfect working condition. Each unit is securely placed in a custom-fitted foam mold inside a sturdy wooden crate to prevent any movement during transit. The machine is covered with protective film to avoid scratches and dust accumulation. All fragile components are individually wrapped and cushioned. The packaging also includes clear handling instructions and warning labels to guide safe transportation and unloading.

Shipping:

We offer worldwide shipping for the Laser Glass Cutting Machine through reliable freight carriers. The shipping options include air freight for faster delivery and sea freight for cost-effective bulk orders. All shipments are fully insured and tracked from our warehouse to the destination. Our logistics team coordinates with customers to arrange convenient delivery times and provides all necessary documentation for customs clearance. Special care is taken to handle the machine with expertise to ensure it reaches you in optimal condition.

![]()